Model | Capacity [l] | Length [cm] | Width [cm] | Height [cm] | Opening diameter [cm] | Wall thickness [mm] | Threaded hole (plastic) [inch] |

SP-90 | 90 | 80 | 60 | 20 | 16 | 3 | ¾ |

SP-90V | 90 | 80 | 20 | 60 | 16 | 3 | ¾ |

SP-150 | 150 | 80 | 60 | 35 | 16 | 4 | ¾ |

SP-400 | 400 | 125 | 101 | 35 | 22 | 6 | 1 |

Specific References

1. select a DECORATIVE TANK, which matches the colour scheme of your surroundings and has a capacity suitable for you.

2. measure the diameter of the downpipe and select a suitable RAINWATER COLLECTOR .

3. match the diameter of theconnecting hose between the collector and the tank (most collectors have an outlet of 32 mm)

4. match the TANK with the colour of the rainwater tank.

If you wish, you can equip the set with a DRAIN HOSE to empty the tank during winter.

Drinking water tanks are manufactured using rotomoulding technology, which allows the tanks to be produced as a whole, without the need to weld individual components together, which has a beneficial effect on the mechanical strength of the tank. Polyethylene tanks are lighter than their steel or resin counterparts. Tanks made of non-toxic polyethylene are ideal for storing foodstuffs as well as technical substances used in various production processes. The polyethylene material prevents the growth of algae by being impermeable to sunlight. The tank can withstand temperatures from -20 to +80 °C.

The proposed tanks are ideal for:

-storing drinking water or other food-grade liquids both indoors and outdoors,

-the construction of buffer tanks to be used in the event of pressure drops or water shortages,

-to store water for fire-fighting purposes, laundry or dishwashing,

-supplying water in the event of a shortage of water on distribution vehicles,

-collecting and using rainwater, which can be used for irrigation or toilet flushing, etc.

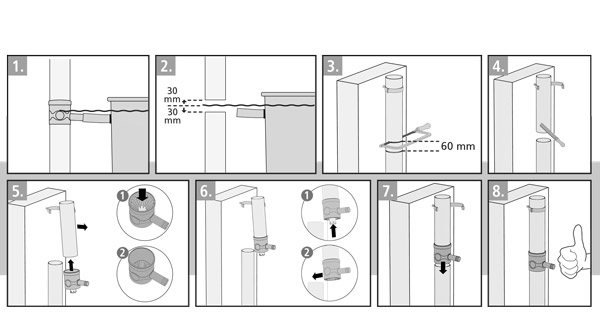

The polyethylene tanks have a polypropylene lid equipped with a vent with anti-fungal protection and threaded connections. Additional inlet and outlet openings can be provided on request. Here is how to properly assemble the spigots.

The hole for the spigot should be drilled with a hole saw in the centre of a flat surface located at the bottom of the tank, approximately 10 cm above the bottom of the tank. The diameter of the hole should be equal to the diameter of the spigot.

Place a gasket on the spigot and then, from the centre of the tank, pass it through the pre-drilled hole. If there are any problems with translation, the spigot can be lightly hammered in with a rubber mallet. Place a second gasket and nut on the spigot protruding from the tank.

Tighten the nut all the way, e.g. with a pipe chain spanner. Then clean the tank and the spigot of any shavings that may have occurred during assembly.

All tanks have the necessary approvals and certificates to allow the tanks to come into contact with foodstuffs.

| Capacity | Image | Unit price |

|---|---|---|

| 90 l |

|

|

| 90 l |

|

|

| 90 l |

|

|

| 90 l |

|

|

| 90 l |

|

|

| 90 l |

|

|

| 150l |

|

|

| 150l |

|

|

| 150l |

|

|

| 400l |

|

|

| 400l |

|

|

| 400l |

|

|

| 400l |

|

|

| 400l |

|

|

| 400l |

|